In Mining, Construction and Engineering Industries, Caterpillar, Komatsu, Volvo and Belaz are the main brands supplying the world with their wonderful tools and vehicles, but for better using these machine, we should and must know some basic knowledge of these parts.

OTR Wheel Rim | 1 Piece wheel rim | Wheel rim Base |

2 Piece wheel rim | Wheel rim Base + Side ring/flange | |

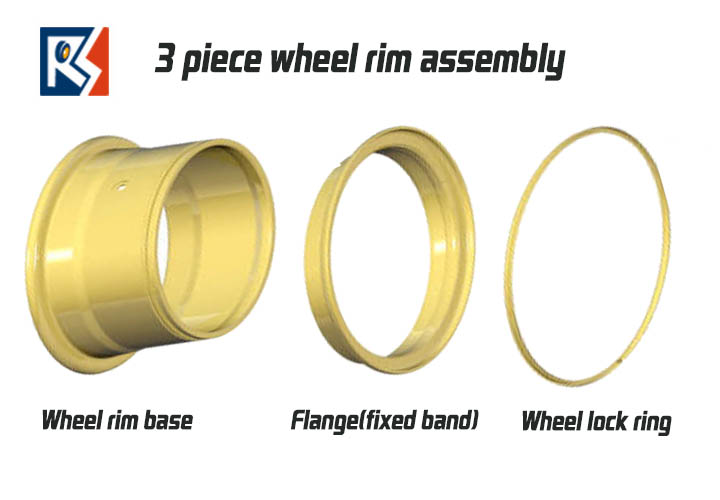

3 Piece wheel rim | Wheel rim Base + Side ring/flange + Lock ring | |

4 Piece wheel rim | Wheel rim Base + Side ring/flange + Lock ring + Bead seat band | |

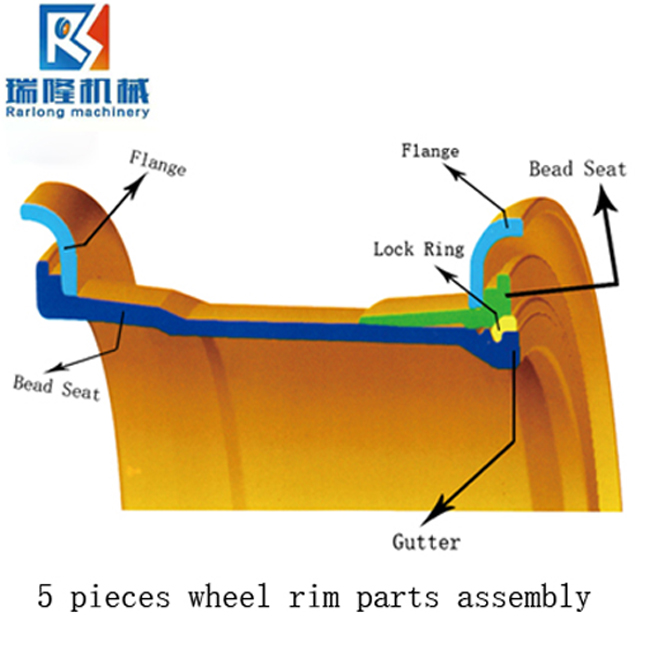

5 Piece wheel rim | Wheel rim Base + Side ring/flange*2 +Lock ring + Bead seat band | |

7 Piece wheel rim | Wheel rim Base + Lock ring*2 + Bead seat band*2 + Side ring/flange*2 |

For multi-piece wheel rim assembly, it consists of two or more parts, generally speaking, including 3pcs, 5pcs, 7pcs wheel rim assy. One of these parts is a side or locking ring which support the tyre and other components on the wheel rim assembly by interlocking the components when the tyres are inflated. Rarlong Machinery is a comprehensive mabufacturer, supplying customers including WORLD TOP BTRANDS, like CATTERPILLAR, VOLVO, KOMATSU, BELAZ, etc. all of these components above.

For the technicians, we must aware that there are some possible dangers of working on large machinery tyres. One of these danger is during the release of the pressured tyre on multi piece wheel rim assembly.

Single-piece rim wheel accidents occur when the pressured air contained in the tyre is suddenly released, either by the bead breaking or by the bead slipping over the rim flange. In a multi-piece rim wheel accident, the wheel components separate and are released from the rim wheel with violent force. The severity of the hazard is related not only to the air pressure but also to the air volume.

The amended safety standard for servicing single-piece and multi-piece rim wheels has four major requirements:

Training for all technician whose daily routines are repair and check the wheel rims.

Training for the supply chain employee who purchased compatible components.

Training the employee to know the industry accepted procedures which can minimize the potential injury.

Training the employee to know the utilization of proper equipments and tools, such as clip-on chucks, restraining devices or barriers to retain the wheel components during the tyre inflation and deflation.

According to the industry data, there has been more than a 70% reduction in multi-piece rim wheel servicing injuries since the original standard was issued in 1980 – based on a review of the record of multi-piece rim wheel accidents investigated by OSHA. Similar results have been experienced with the regulation of single-piece rim wheel servicing where workers also face a significant risk of serious injury or death.

Safety Procedures recommending are below, include:

Standing to one side and keeping your face above the fender when checking or inflating the tyres

Remove the valve core to deflate the tyre completely before removing the tyre from the rim

Mount and remove tyres from the narrow ledge side of the wheel and avoid damaging the tyre beads

Mount only rims and tyres of compatible diameter and width

Inspect the rim flanges, bead seating surfaces and tyre for defects and foreign particles. Replace any rim that is rusted, cracked, broken, bent, corroded or damaged

Do not exceed the vehicle or manufacturer’s recommended inflation pressure and use valves that are appropriate for the use of the tyre

Anyang Rarlong Machinery Co., Ltd.

Contact:Mr. Yang Poping

Tel:+86-372-2517069

Phone:+86 13803722027 Mobile/Wechat

E-mail:sales@rarlongmachinery.com

Add:South Guangming Road,Anyang City,Henan Province,China